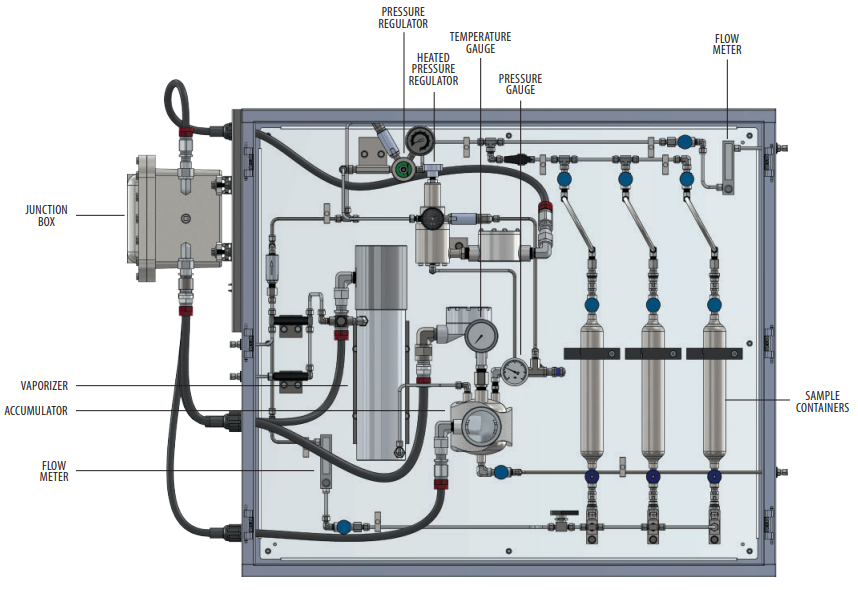

CAC – LNG Sampling System

THE WELKER LNG SAMPLING SYSTEM FACILITATES THE VAPORIZATION AND CONDITIONING OF A SAMPLE OF LNG FROM ITS LIQUID STATE TO A GASEOUS STATE IN COMPLIANCE WITH THE INTERNATIONAL STANDARDS FOR LNG SAMPLING

WELKER’S REVOLUTIONARY LNG DESIGN

While other LNG probes and systems rely on maintaining temperatures up to the vaporization stage, which could cause potential

compositional separation and fallout, the Welker LNG probe eliminates this possibility. The patented check valve design allows for small amounts

of LNG to enter the sample system at the probe tip and immediately begin the gasification process. This not only eliminates the possibility

of heavier components escaping the system and returning back into the process, it also greatly reduces the line pack and increases

measurement accuracy and timeliness of results. This patented check valve design is an innovation in LNG sampling application and is yet

another example of Welker products leading the way in the sampling industry.

SYSTEM COMPONENTS

SPECIFICATIONS

LNG SAMPLE PROBE

- Materials of Construction: 316/316L Stainless Steel

- Maximum Allowable Operating Pressure: 275 psig @ -20 °F to 100 °F (18 barg @ -28 °C to 48 °C)

- Minimum Design Inlet Temperature: -265 °F (-165 °C)

- Patent: U.S. Patent 8,347,694

LNG SAMPLING SYSTEM

- Maximum Allowable Operating Pressure: 275 psig @ -20 °F to 120 °F (18 barg @ -28 °C to 48 °C)

- Maximum Vaporizer Temperature: 250 °F (121 °C)

- Energy Output: 2000W

- Minimum Design Inlet Temperature: -265 °F (-165 °C)

- Enclosure Dimensions: 48″ x 17″ x 42″ (Width x Depth x Height)

- Industry Standards:

- API 14.1/

- API 17.10.2/

- GPA 2166/

- ISO 8943

- Electrical Area Classification: NEC Class I, Div. 1, Groups C & D, T3

Calibration gas cylinder

Calibration gas cylinder Calibration gas detector

Calibration gas detector Colorimetric gas detection tubes

Colorimetric gas detection tubes Combustible gas detector

Combustible gas detector Cylinder regulator

Cylinder regulator Fixed gas detector

Fixed gas detector Four gas detector

Four gas detector Gas detector

Gas detector Gas detector accessories

Gas detector accessories Gas monitor panel

Gas monitor panel Multi-gas detector

Multi-gas detector Oxygen gas detector

Oxygen gas detector Safety and rescue equipment

Safety and rescue equipment Toxic gas detector

Toxic gas detector VOCs gas detector

VOCs gas detector